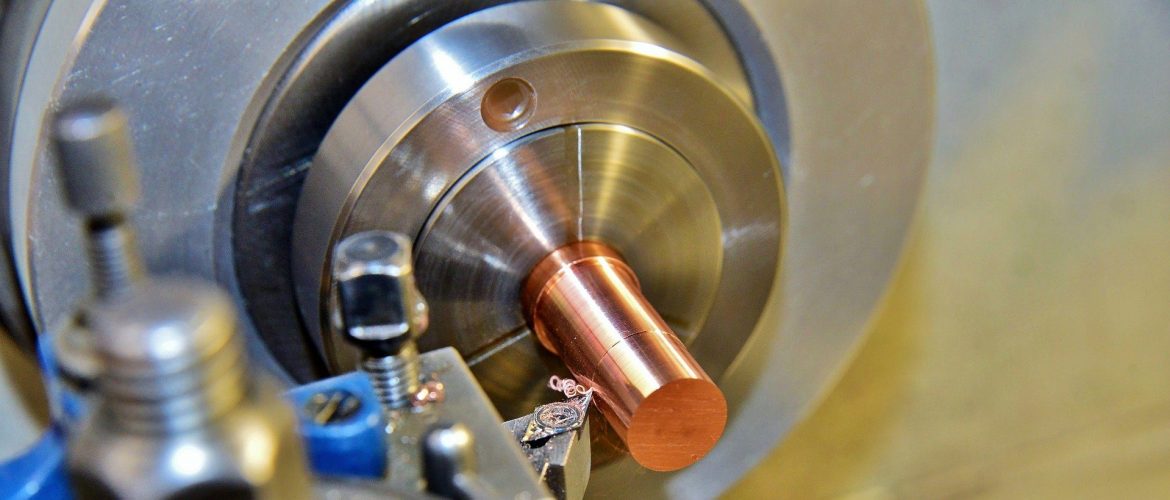

Top Identifiable Signs of a Poor Manufacturing Process

6 Top Signs Your Job Shop Manufacturing Process Needs Attention!

With manual and disparate systems your manufacturing job shop can be chaotic. Should your operation not have an automated Manufacturing Process then you could suffer from some of our highlighted symptoms below?

Inconsistent Costing

From manual input of timesheets to manual job cards. Managing time estimates will be a challenge when your system is automated.

Poor Inventory Control

Without a robust ERP and front end solution, it gets very difficult to maintain good stock levels drive correct procurement processes, allocate correct items to a job and not to be over stocked

Disparate Systems

Poor data control between your manufacturing work shop and back office accounting, leads to incorrect pricing, delayed orders and poor control of internal processes

Inconsistent Quotes \ Assessments

With manual systems that do not integrate, generally many manufacturing job shops using excel to assess and quote jobs cannot quote consistently.

Lost Jobs

Jobs loaded onto a system can cause them to go missing, indeed not even starting the process of been assessed and quoted. Many engineering firms struggle with tracking of job statuses, this inherently reduces customer experience

Poor Quality Control

Job shops do not have real-time insights into their operations from manual documentation and processes. This creates scenarios where poor checks and non compliance of internal procedures become prevalent and problematic.

Automating Your Manufacturing Process

Many Manufacturing Job Shops experience one or more of the above symptoms in the daily manufacturing process, due to manual processes such as manual job cards, manual time keeping on work centre activities and the good old fashioned spreadsheets.

This leads to a chaotic work shop environment, where quality control is poor, jobs go missing and inconsistent costings on your jobs.

Improve Your Operations

Bringing your disparate systems into one holistic solution, not only improves your operational efficiencies it also reduces time spent on manual data and admin capturing, giving you more time to spend on what’s import to drive profits and reduce costs.

We can help you achieve consistent job costing and many more area’s which need attention.

Download our E-book now or sign up for a free consultation.