What is JIT? And how can it help you?

What is Just in Time (JIT)?

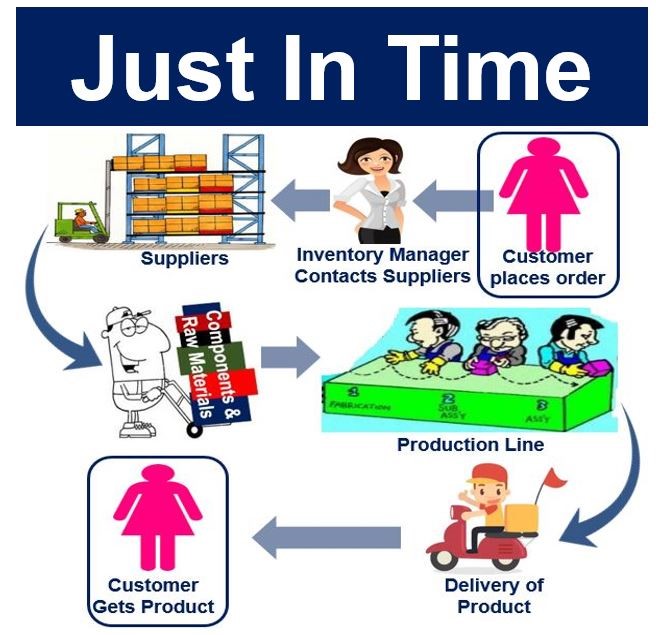

Just in time is a manufacturing concept workflow methodology aimed at reducing costs and delivery times within a manufacturing ecosystem for the procurement and distribution of materials.

One of the most successful implementation of this methodology was Toyota of Japan. They pioneered the concept from the early 1970s, which lead to customer demands been meet with minimal delays. The JIT concept did not only apply to materials but also personal and plant resources.

The main goal of the JIT concept is to minimize or have zero stock\inventories across the organisation and its supply chain. This method allows for the maximaisation of Return on Investment.

Because the JIT methodology was so successful with Japanese manufacturing entities, it is now used around the world.

Many of us do use procurement orders driven by the job

In a make-to-order, fabrication, service and repairs entities, you find many of your jobs have once off buy-outs linked to the job. This is due to you not keeping stock or this could be a non-stock item.

What are the advantages of Just In Time (JIT)?

- JIT can achieve better product quality through elimination of waste in production.

- The JIT approach can reduce the cost of inventories and inventory requirements.

What are the disadvantages of Just In Time (JIT)?

- The JIT system does not cope well with sudden changes to demand and supply.

- Implementing the system can be challenging and time-consuming and can be expensive to deploy.

Is Just in Time (JIT) right for my business?

If Just in time is applied correctly to your manufacturing operations, this will be a powerful concept to help you improve quality, turnaround times and cash-flow. But is it right for your business? Well most manufacturing entities do employ some kind of JIT with buy-outs driven by the actual job.

Most small to medium manufacturing operations use manual processes to drive jobs and this is where the chaotic workflow arises as there is no automation to employ better processes such as Just in time

How can Just-In-Time (JIT) JIT be applied successfully?

- Create a stabilized work schedule environment.

- Establish long-term supplier-customer relationships.

- Create a purchasing philosophy on supporting frequent small purchases.

- Encourage and ensure employee discipline.

- Identify value-added and non-value added items in shop floor activities.

- Ensure top management commitment for effectiveness and successful implementation.

A solution to help you deploy Just in time

With JobPRO you can create virtual job cards on a live up-to-date environment, with Purchase order integration to your ERP system we can create purchase orders driven by the job, employing the just in time philosophy.

Download our E-book now or sign up for a free consultation.

Need more information? Contact us now!