Take Control of Manufacturing Lead Time With Job Shop Management Software

Reduce Customer Lead Times

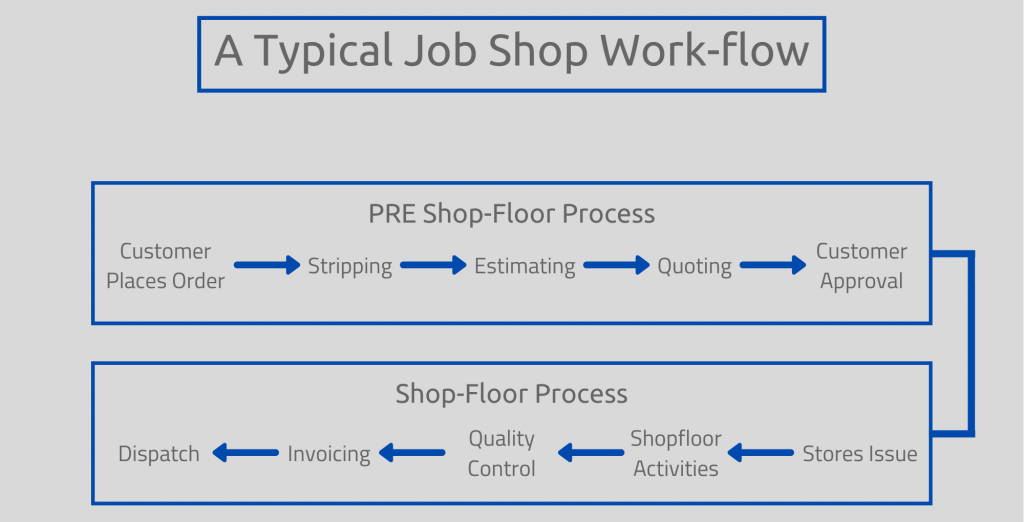

Let’s look at the case of specialised hydraulics manufacturer receiving a repair request. The process from receiving the request to delivering the finished item to the customer and Improve Job Shop turnaround times.

A Basic Info-Graphic To a Manufacturing Job Shop Work-Flow

The management truism, “You can’t manage what you can’t measure” is especially true of Manufacturing Lead Time. Job shop management software when integrated with ERP enables the capture and measurement of every step in the process across all departments. Having all the steps captured in a workflow allows the business to monitor and measure progress each step of the way so that you can Improve Job Shop turnaround times

JobPRO provides integration, cross-department up-to-the-minute view on the progress of every step on every job. JobPRO shows shop-floor employees at each station what they need to do next, what parts are involved and how long they have to complete it. The warehouse, Planners, Foremen, Sales and Finance have the kind of overview that allows them to plan and when necessary re-plan efficiently. That improves the effectiveness of all communication with customers and suppliers alike.

JobPRO delivers hard information to assist in managing and reducing your manufacturing lead time.

- The system provides notifications and reminders to the responsible parties when they have a task to complete so that work is not forgotten or unduly delayed.

- Customer satisfaction benefits from an integrated system measuring and monitoring each contribution to manufacturing lead time. Customers can be given realistic delivery estimates and be kept informed of normal progress or unexpected delays.

- The cross-company view of up-to-date labour and stock availability supports normal estimating and scheduling, as well as responding to changes.

- In the day-to-day of manufacturing things often go awry or don’t neatly follow the plan. The impact on manufacturing lead time of daily problems or obstacles that introduce delays is immediately visible to all departments.

- JobPRO allows the team to embed quality management checklists and quality incident reporting into the worksheets assigned to each station on the production floor.

With JobPRO you can get to know your manufacturing lead times and keep track of your manufacturing workflow across all departments from beginning to end.

Download our E-book now or sign up for a free consultation.

Or call us today for a obligation free demo.