How To Improve Order To Delivery Times

In our competitive world customers do not like waiting. This is especially true in the Job Shop Manufacturing industry as many clients have deadlines or obligations they have to meet. When there is a breakdown in the process to deliver on time as required, clients start to get frustrated, this causes a strained relationship between customer and supplier. Manufacturing lead Time has become very important to maintain customer relations.

For Job Shop Manufacturers, the consequences of not meeting deadlines promised can go far beyond frustration. Your customers may start looking for other suppliers as your competitors might introduce products quicker and better to their customers, the consequence of this is they will slowly start taking your share of the business.

Longer lead times are also linked to quality control issues that get picked up by the client. Then there has to be rework done, which ultimately adds to the lead time. Many Job Shop Manufacturers don’t always take this into account. The promised lead time is 5 days, but unfortunately the job is only delivered in 7 days(2 Days late), then there are quality issues and rework has to be done which takes another 2 days and we still have to factor in delivery time as well. So in fact a job that should have taken 5 days has now effectively 9 days or more.

Manufacturing lead time is connected with customer service and in todays world, customer retention is more important than ever. With an ever growing competitor base, companies are finding it more and more difficult, to retain customers and to maintain margins.

Margins

Nowadays margins are getting smaller as more companies enter the market, more competition is raised and company margins start to fall. But as margins get smaller expenses increase. This becomes a very difficult balancing act for manufacturing businesses as this balancing act can be the reason if a company fails or succeeds.

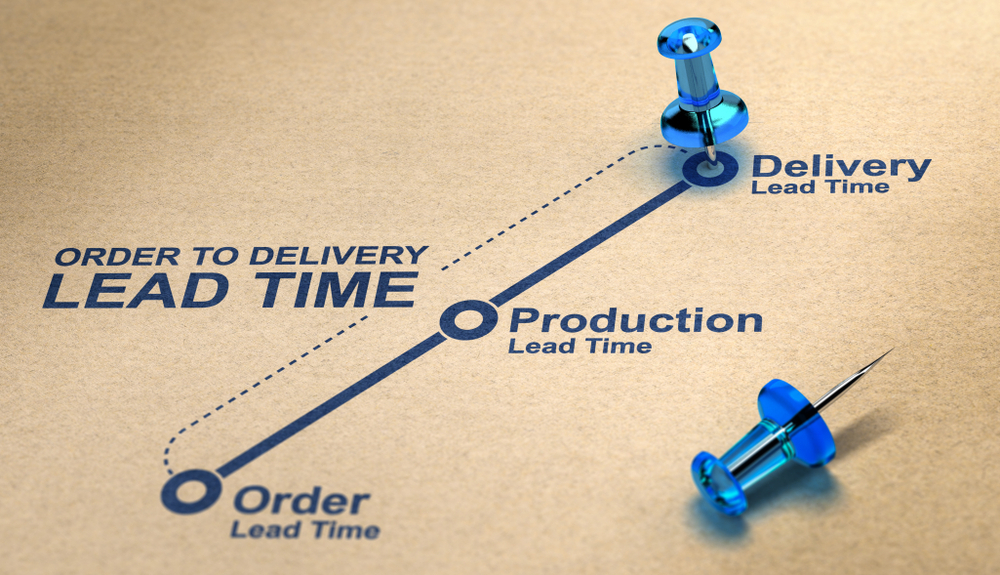

Reducing and accurately forecasting lead times is a critical element of any Job Shop Manufacturing operation. Businesses should strive to maintain promised delivery times with top notch quality. This in turn improves customer satisfaction and retention.

What are the main contributors to extending Manufacturing Lead Times?

Visibility

Many Job Shop Manufacturers employ manual processes to drive the shop-floor. This usually comprises of printed job cards and excel spreadsheets. Often there are cases where jobs go missing an example of this is a repair was received and put into a corner of the workshop, out of sight out of mind.

There is no live updates of jobs, so essentially there is no tracking of a job and how long the job sits at each work station.

There is no immediate communication when customer asks what is the status of their job. An example of this, is when you literally have to go and hunt for the job on the floor find out what the status of the job is and then report back to the customer. This is time intensive and sometimes because you do not have information on hand, we forget to give information back to the customer.

Complex Quoting

Many Job Shop Manufacturing operations have poor quoting systems, generally using excel spreadsheets. Quotes go out to customers incomplete missing items, or prices have not been updated. This either leads to requoting which takes time or the customer has excepted the quote and the business loses money on the deal.

Many quotes that go out to customers are missing items such as services items, this can be attributed to operations not having BOMs or KITs. In an automated process templates can be created, to avoid this mishaps from occurring.

Maintaining Inventory

In many cases inventory is not managed properly, shop-floor employees don’t have access to the accounting system and cannot confirm if stock is available or not. In certain situations stock has been booked to multiple jobs, creating huge problems in the workshop. Minimum stock levels are also not maintained and all these small problems, delay delivery times.

Integration

With manual processes comes duplication of work. A manual job card is completed and then has to be captured onto an accounting platform, this is especially true for quotes which are compiled on an Excel spreadsheet and then captured in the accounting system once the quote has been approved.

With manual capturing and duplications, typo’s are often the demons that cause poor quoting and incorrect pricing. This can have an effect on margins and delivery times.

How can a business improve Manufacturing lead Time ?

Fourth Industrial Revolution

We have moved into a digital world, and automating your operations will give you a competitive edge over competition. Digitizing your operation from pre shop-floor to your shop-floor process enables you to get insight into your daily operations.

From checking a status of your job to get costing per job at a click of a button, you will have better control and ultimately improve your manufacturing lead times.

Download our E-book now or sign up for a free consultation.

Or call us today for a obligation free demo.